Microchannel heat exchangers have undergone significant advancements since their inception, becoming essential components in various applications, including HVAC systems, automotive cooling, and refrigeration. Their compact design and improved efficiency have made them a prominent choice in modern thermal management solutions.

Historical Context

The journey of microchannel heat exchangers began in the early 1980s, aiming to address the limitations of traditional heat exchangers, such as size and weight. The introduction of microchannel technology allowed for reduced refrigerant charge and enhanced heat transfer capabilities. This innovation was particularly crucial in industries where energy efficiency and space constraints are critical.

Technological Advancements

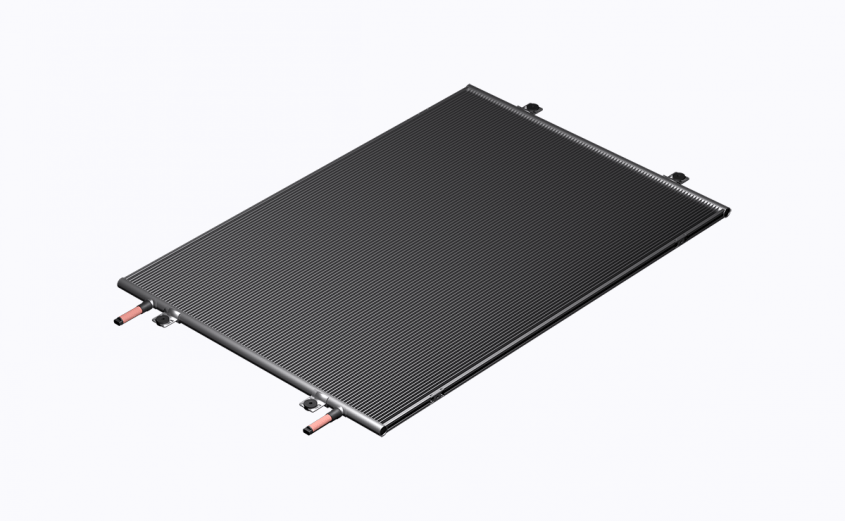

Recent developments in microchannel heat exchangers focus on optimizing fluid dynamics and material properties. The use of aluminum as a primary material has significantly decreased the weight of these devices while maintaining structural integrity. Advanced manufacturing techniques, such as extrusion and welding, have enabled the production of intricate channel designs that enhance surface area and improve heat transfer rates.

One of the leading manufacturers in this domain is Kaltra, which specializes in high-performance microchannel heat exchangers. Their extensive range of products illustrates the potential of this technology for various industrial applications. For more information, you can explore their offerings here: https://kaltra.com/microchannel-heat-exchangers.

Applications in Modern Industry

The versatility of microchannel heat exchangers allows them to be utilized across different sectors. In automotive engineering, they have become increasingly integrated into vehicle cooling systems, providing superior performance in a compact footprint. This transition is pivotal as the automotive industry shifts towards more fuel-efficient and environmentally friendly designs.

HVAC and Refrigeration

In HVAC systems, microchannel heat exchangers contribute to increased energy efficiency and reduced operational costs. Their ability to operate effectively in varying conditions makes them ideal for commercial and residential air conditioning systems. Similarly, in refrigeration, these heat exchangers enhance the overall performance of cooling cycles, leading to lower energy consumption and improved reliability.

Future Directions

The future of microchannel heat exchangers looks promising, given the growing demand for energy-efficient solutions in the face of climate change. Innovations in nanotechnology and surface coatings are expected to further elevate their performance. Additionally, the ongoing research into alternative refrigerants aligns with global sustainability goals, making microchannel heat exchangers a focal point in the development of greener technologies.

Challenges Ahead

Despite their advantages, the widespread adoption of microchannel heat exchangers faces challenges. Issues related to manufacturing consistency, cost-effectiveness, and compatibility with existing systems require ongoing research and development. Addressing these challenges will be crucial for maximizing the potential of microchannel technology in diverse applications.

A Result

The evolution of microchannel heat exchangers reflects a significant shift in thermal management technology. Through continuous innovation and adaptation, these devices have established themselves as vital components in achieving energy efficiency and compact design across various industrial sectors. As the demand for sustainable solutions grows, microchannel heat exchangers will undoubtedly play an integral role in shaping the future of thermal systems.